Our Partnership with Nuyarn®: Performance, Comfort, and Sustainability

At Pinebury, we believe cycling apparel should do more than just fit—it should enhance every ride. That’s why we partner with Nuyarn®, a revolutionary merino wool technology that offers superior performance without compromising comfort.

Rather than chasing marginal aero gains that are irrelevant to most cyclists, we focus on what truly matters: a fit that moves with you, regulates temperature and moisture, and feels exceptional in changing conditions. Nuyarn® amplifies the natural benefits of merino wool, creating garments that are lighter, stronger, and more breathable than traditional wool or synthetic alternatives.

By choosing Pinebury, you’re choosing apparel designed for real-world performance—comfortable, durable, and built to adapt. Whether you're on an all-day adventure or a quick ride before sunset, our gear moves with you, providing comfort and performance in every mile.

The World's first performance wool

While merino has some great qualities, it is also susceptible to poor abrasion performance, holes, pilling, moisture retention and insulation that is substandard.

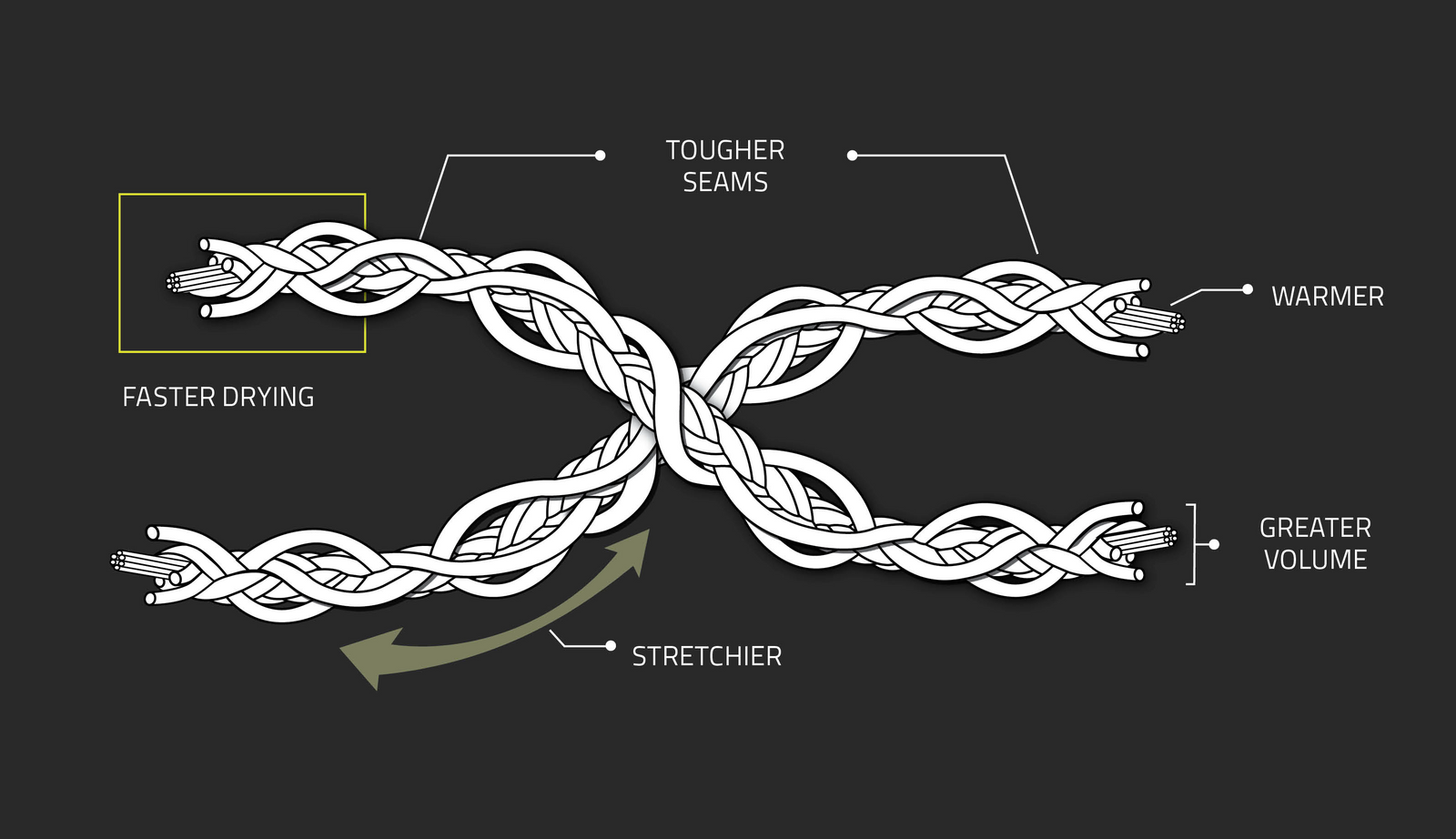

Nuyarn® does not twist the fibers, instead, it drafts merino fibers along a high-performance filament resulting in two-ply yarns with much more volume and aeration.

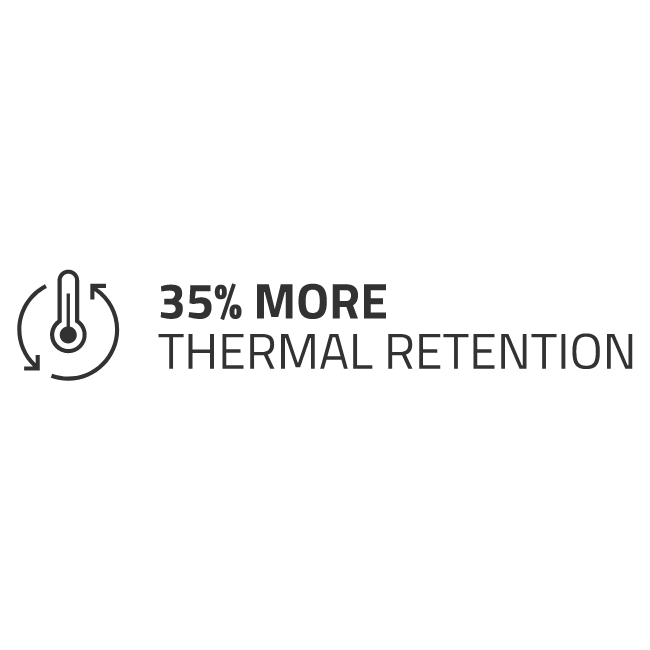

The two-ply yarn structure is 35% finer than yarns spun on a conventional ring frame and combined with the Nuyarn® thermal advantage, offers the capacity to engineer much lighter, high performance fabrics as a result.

It is not ring spun. It is not core spun. Nuyarn® is twist-free spinning.

natural Performance

The Nuyarn® method of twist-free spinning allows us to create products that outperform traditional merino and synthetics, offering a natural enhancer to athletic performance. Unlike synthetic treatments, Nuyarn® technology doesn’t rely on chemical coatings—the performance benefits are built into the yarn itself, meaning they last for the life of the garment and won’t wash out. This innovative process results in fabric that is lighter yet stronger, dries five times faster, and offers unmatched breathability and stretch. In addition to regulating temperature and moisture, Nuyarn® provides inherent UV protection, shielding you from the sun’s harsh rays without the need for chemical additives. The result? Apparel that works with your body, delivering comfort, durability, and performance in all conditions.

Abrasion resistance

Comparing core spun & ring spun to Nuyarn from 8000 rubs to 30000

Nuyarn is Performance and sustainability

The biggest impact of all comes from durability. Nuyarn® garments have been independently tested to last 8.8x longer than ordinary merino. That means for every one Nuyarn® garment, the rest of the industry needs to source materials, energy, processing, and distribution for 9 garments.

Nuyarn®Technology creates incredible natural volume and aeration in the yarn, normally twisted out by ring and core spinning technologies. Nuyarn® fabrics use less wool, because the wool fibers can perform more like they do in nature. The knock-on effect is that Nuyarn® uses less resources such as water, dyes, energy, and transport. This even extends to strong wool — Nuyarn® advanced drafting techniques create a more consistent product and can use longer wool fibers that are normally destined for landfill

All our wool from farm to fabric is Responsible Wool Standard (RWS) certified.

In addition, all wool is from certified non-mulesed sheep that are free to roam and are shorn annually. All spinning facilities are accredited with Bluesign® and meet or exceed international or regional standards. TMC / Nuyarn is also accredited to Oeko-Tex® 100 class one standard, which certifies that our processes do not use anything considered to be harmful to people, animals, or the environment.